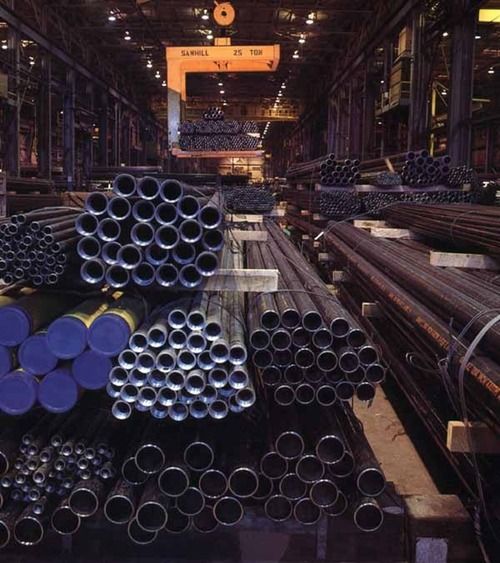

Air Preheater Tube

Product Details:

- End Protector Plastic caps or metal protectors available

- Tolerance 0.01 mm to 0.05 mm

- Product Type Air Preheater Tube

- Surface Finish Smooth / Polished

- Application Used in air preheaters of boilers, furnaces, and heat exchangers

- Connection Welded or seamless coupling

- Material Carbon Steel

- Click to View more

X

Air Preheater Tube Price And Quantity

- 1 Unit

- Wooden case or bundle packing

- Up to 600°C

- High due to surface treatment

- Depends on size and thickness

- High thermal efficiency, durable, easy to install

- 5000 tons per month

- 100% hydrostatic tested

Air Preheater Tube Product Specifications

- 25 mm to 76 mm

- Non-alloy or alloy as per requirement

- ASTM A213/A249, DIN 17175

- Air Preheater Tube

- 0.01 mm to 0.05 mm

- Plastic caps or metal protectors available

- 1 m to 12 m or customized

- 2 mm to 6 mm

- Cold Rolled / Hot Rolled

- Used in air preheaters of boilers, furnaces, and heat exchangers

- Smooth / Polished

- Welded or seamless coupling

- Round

- Carbon Steel

- Galvanized, Annealed or Painted

- Customized

- Wooden case or bundle packing

- Up to 600°C

- High due to surface treatment

- Depends on size and thickness

- High thermal efficiency, durable, easy to install

- 5000 tons per month

- 100% hydrostatic tested

Air Preheater Tube Trade Information

- Telegraphic Transfer (T/T), Cheque

- 5-10 Unit Per Week

- 2 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia, Australia

- All India

Product Description

AIR PRE-HEATER TUBES

Supply & Exporter of Air Pre-heater Tubes are made available to the customers in various Grades, Standards and other Specifications, in order to respond to the market demand efficiently.

AIRPRE HEATER TUBE:

- Standard: BS,ASTM

- Material: BS 1775/64/ERW Gr.11,BS 6323 PT-V ERW,ASTM A 423 A Gr.1(Carton Steel)

- Outer Diameter: 50.8 mm to 63.5 mm

- Wall Thickness: 2.03 mm to 4.06 mm

- Length : Various

Superior Corrosion Resistance & Surface Treatment

Air Preheater Tubes feature high corrosion resistance provided by surface treatments like galvanizing, painting, or annealing. This protection extends the tubes operational life and preserves performance even in harsh environmental conditions. A smooth or polished finish makes the tubes ideal for heat exchangers, reducing fouling and promoting consistent airflow.

Wide Temperature Range and Thermal Efficiency

Withstanding temperatures up to 600C, these tubes excel in demanding thermal applications. Their high thermal efficiency enhances boiler and furnace performance, leading to better energy utilization. Suitable for a variety of systems, their robust design ensures stable operation over long periods.

Customized Packing and Quality Assurance

Tubes are packed in sturdy wooden cases or bundles, safeguarded with plastic caps or metal protectors to prevent damage during transport. Each piece is 100% hydrostatic tested, ensuring premium quality and reliability before delivery. Flexible options in size, connection type, and section shape are available to meet specific project requirements.

FAQs of Air Preheater Tube:

Q: How are the Air Preheater Tubes protected against corrosion?

A: These tubes employ advanced surface treatments such as galvanizing, painting, or annealing, which confer high resistance to corrosion, making them suitable for harsh environments and extending their service life.Q: What is the maximum temperature these tubes can withstand?

A: Air Preheater Tubes are engineered to operate efficiently at temperatures up to 600C, making them ideal for boilers, furnaces, and heat exchangers in industrial settings.Q: When should Air Preheater Tubes be inspected?

A: Each tube undergoes a 100% hydrostatic inspection during production to ensure leak-proof performance and structural integrity. Regular inspections should follow installation as part of routine maintenance.Q: Where can these tubes be applied?

A: They are particularly suited for use in air preheaters, boilers, furnaces, and heat exchangers across various industries that require high thermal efficiency and durability.Q: What are the available packing and end protection options?

A: Air Preheater Tubes are securely packed in wooden cases or bundles and can feature either plastic caps or metal protectors on the ends to prevent damage during shipping and handling.Q: What is the benefit of choosing tubes with precise dimensional tolerances?

A: Tubes manufactured with tight tolerances (0.01 mm to 0.05 mm) ensure accurate fitment, optimal air flow, and improved heat transfer efficiency, reducing energy losses and simplifying installation.Q: How does ordering customized sizes and materials work for these tubes?

A: Customers can specify their requirements for diameter, thickness, length, alloy composition, and surface finish. The tubes are produced according to these specifications, and the supplier coordinates with clients to meet exact project needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email