Commercial Boiler Tube

Product Details:

- Product Type Commercial Boiler Tube

- Tolerance 0.1 mm

- Application Industrial Boilers

- End Protector Plastic Caps

- Connection Welded

- Surface Finish Polished

- Material Carbon Steel

- Click to View more

X

Commercial Boiler Tube Price And Quantity

- 1 Unit

Commercial Boiler Tube Product Specifications

- 0.1 mm

- Commercial Boiler Tube

- 5 mm

- Plastic Caps

- Up to 12 meters

- Industrial Boilers

- Non-Alloy

- Carbon Steel

- ASTM A192

- Round

- Hot Rolled

- 2 inch (50.8 mm)

- Welded

- Polished

- Custom/Standard

- Anti-corrosion Oil Coating

Commercial Boiler Tube Trade Information

- Telegraphic Transfer (T/T), Cheque

- 5-10 Unit Per Week

- 2 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- All India

Product Description

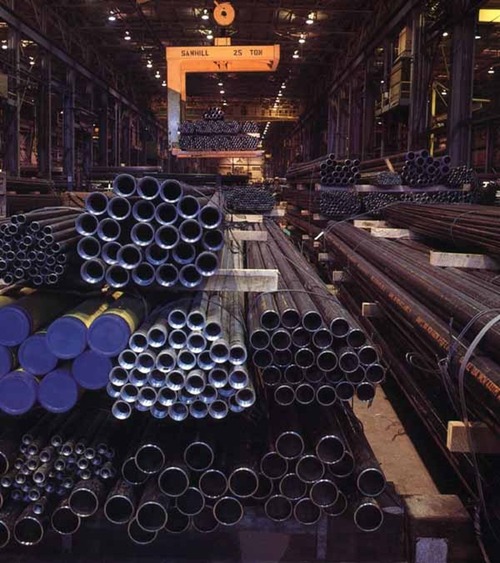

BOILER TUBES

Supply & Exporter of Boiler Quality Tubes & Air Pre Heater Tube are made available to the customers in various Grades, Standards and other Specifications, in order to respond to the market demand efficiently.

BOILER TUBE :

Standard: BS,ASTM,

Material: BS3059 Gr.320,Gr.360,SA210 GR.A1,A179, ASTM A213 T11/T22/T5/T9/T91

Outer Diameter: 12.7 mm to 101.6 mm

Wall Thickness: 2.03 mm to 9.53 mm

Length : Various

AIRPRE HEATER TUBE:

Standard: BS,ASTM

Material: BS 1775/64/ERW Gr.11,BS 6323 PT-V ERW,ASTM A 423 A Gr.1(Carton Steel)

Outer Diameter: 50.8 mm to 63.5 mm

Wall Thickness: 2.03 mm to 4.06 mm

Length : Various

Exceptional Temperature and Pressure Resistance

Designed to operate efficiently under extreme conditions, our boiler tubes withstand temperatures up to 550C and high pressure. This makes them ideal for demanding industrial systems where safety and durability are paramount.

Superior Corrosion Protection and Surface Finish

Each tube is treated with anti-corrosion oil coating and features a polished surface, enhancing longevity and reducing maintenance needs. These attributes ensure reliable performance even in corrosive environments such as power plants and manufacturing facilities.

Precision Engineering and Customization

Manufactured to strict tolerances of 0.1 mm, our boiler tubes guarantee seamless integration into your systems. We offer both standard and custom sizes with lengths up to 12 meters, meeting diverse project requirements effectively.

FAQs of Commercial Boiler Tube:

Q: How is the corrosion resistance of the commercial boiler tube achieved?

A: The tubes are treated with anti-corrosion oil coating and use high-quality carbon steel, providing robust resistance to rust and corrosion even when exposed to moisture and steam.Q: What industries commonly use these boiler tubes?

A: Our boiler tubes are primarily used in industrial boilers for steam and hot water transfer, with applications in power generation, manufacturing plants, and large-scale heating systems.Q: When should I opt for custom size boiler tubes?

A: Custom sizes are recommended for installations with unique design requirements or when standard dimensions do not fit existing boiler systems. We accommodate projects needing specific lengths and diameters.Q: Where are the boiler tubes manufactured and supplied from?

A: We manufacture, export, and supply these boiler tubes from India, ensuring reliable delivery and service both domestically and internationally.Q: What is the process for connecting these tubes to a boiler system?

A: The tubes feature welded connections, which provide secure and leak-resistant integration. Welded joints are preferred for maintaining system integrity in high-pressure environments.Q: How does the products tolerance improve installation?

A: With a strict tolerance of 0.1 mm, these tubes offer precision fitting, minimizing installation challenges and ensuring a perfect match for your boiler system.Q: What are the benefits of the ASTM A192 standard compliance?

A: Compliance with ASTM A192 ensures consistent quality, high pressure tolerance, and safety, giving you confidence in the tubes performance and longevity in industrial boiler operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email